The Lack of Capacity Mystery

An HVAC contractor attended services at at an old church and volunteered to install a new heating and air conditioning package unit. To begin the process. the contractor performed a detailed heat load calculation for the church which included the peak occupancy load, local weather, detailed description of construction materials and the building’s location. He determined that he needed a 15-ton packaged unit to satisfy their cooling needs. This generous contractor also paid his employees to install the unit and ductwork out of his own pocket.

The problem arose the first Sunday morning when the newly installed air conditioning unit would not keep the church cool. People inside were hot and uncomfortable; the air being delivered into the occupied space did not feel cold.

The following Monday, he sent his two best service technicians out to the job site. They couldn’t find anything wrong with the unit or its installation. They tried adjusting the refrigerant charge and ended up changing the two compressors, but the unit still did not cool the space as-needed the following Sunday. Out of desperation, the service technicians changed-out the two compressors a second time. Unfortunately the package unit failed to cool yet again. The unit only had to air condition one day a week and it was not even doing that. Summertime had arrived, only making the situation worse… He was at the point of wanting to change the whole package unit, and that’s when I got the phone call.

I scheduled his appointment for Friday afternoon to help him solve this lack of capacity problem. I grabbed my psychrometric chart, temperature meters and headed out. Once at the church, we looked at the air ducts and distribution. The duct sizing was correct and the quality of work was excellent upon inspection. We headed to the roof to examine the 15-ton unit which had two compressors on two independent refrigerant circuits. We radioed his helper down in the space to crank the thermostats to force both stages of compressors to run in cooling mode.

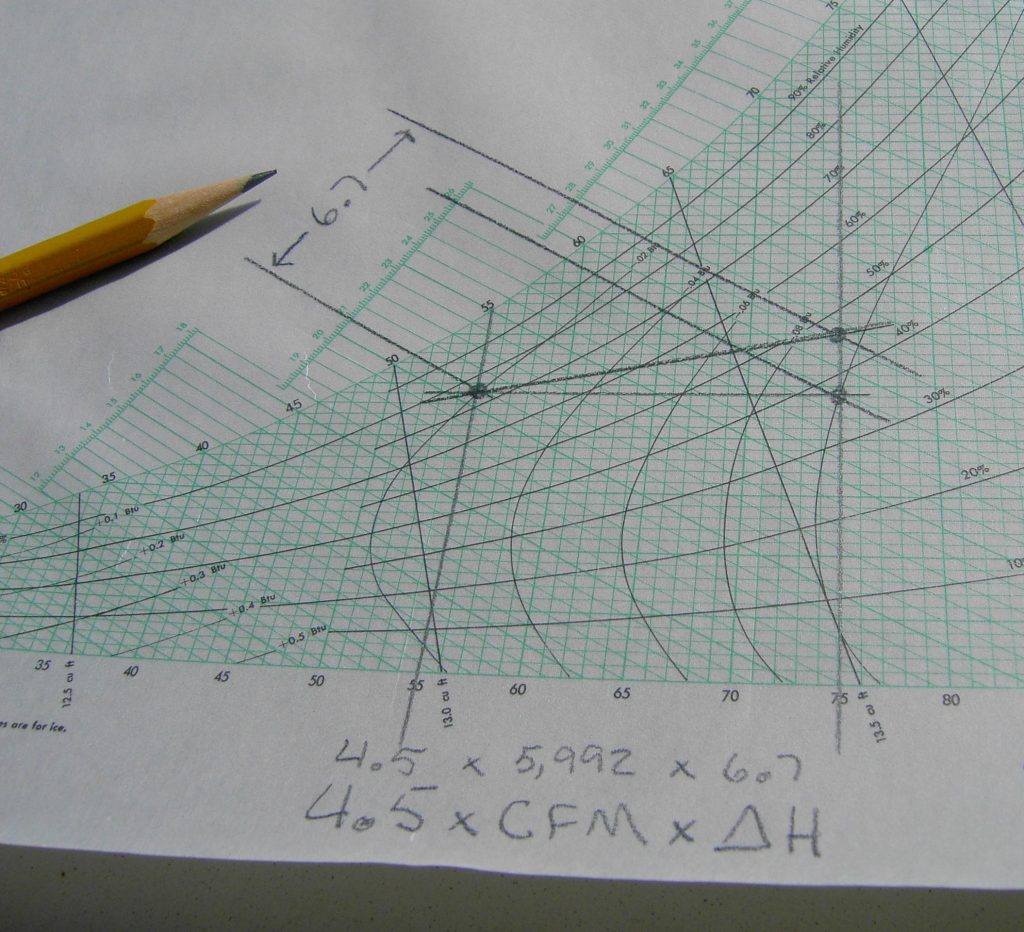

With the package unit running at full speed I calculated the total capacity on my psychrometric chart like the one below. The formula is Total Capacity = 4.5 x CFM x Delta H (enthalpy). The formula breaks down in three easy steps: first is the constant of 4.5, this is the standard for air at sea level with air being 23% oxygen and 77% nitrogen. The second step is to multiply 4.5 by the CFM that was measured at the outlets with a flow hood. Our CFM equaled 5,992. The final and longest step is to find the Delta H (enthalpy). The Delta H (enthalpy) number is found by measuring the sensible and latent differences both entering and leaving the indoor evaporator coil and plotting it out on a psychrometric chart. Sensible heat is also called dry bulb and can be measured on a standard thermometer. When sensible heat is removed you can feel it. Latent heat needs to be measured with a psychrometer. A “sling” psychrometer should be carried by every service technician. The old fashion sling psychrometer gets its readings from a wetted cotton wick that covers a small mercury bulb. This assembly then gets rapidly slung around in the air for 60 second for the latent reading. The newer electronic versions are digital and very fast at measuring both sensible and latent temperatures.

I plotted the sensible heat values both in and out of the evaporator on the psychrometric chart and drew two parallel lines. My numbers were (75F and 55F respectively). I then marked the latent heat number both in and out of the evaporator on the psychrometric chart (61.5F and 51F correspondingly). The latent heat numbers intersected with the previous lines. At this intersection I spun my ruler diagonally on the psychrometric chart and my wet bulb values of 20.8 and 27.5 Btu’s per pound are now easily found. The only item left was to subtract the difference between the two wet bulb values to arrive at the “Delta H” or total heat removed, this number was 6.7. I felt I was getting close to solving the mystery and finding out the true capacity of this package unit. Once I had my total heat removed number of 6.7, I multiplied it by the package units actual CFM of 5,992 and 4.5 for air at sea level to arrive at this unit’s total capacity.

I rapidly worked through the calculations, with everybody was looking over my shoulder for the answer. I multiplied the last figure which equaled 180,658 Btu’s. To my surprise, when I divided that number by 12,000 Btu’s per ton, the results showed 15-= tons of cooling capacity… and psychrometric charts don’t lie. This posed an interesting problem, how could this unit be putting out the correct amount of cooling capacity and not properly cool the space below? We took temperature and CFM readings again with the flow hood and thermometers. The second time I was very carefully noting the results. I punched the numbers into the calculator and plotted the results on the chart; same result. The psychrometric chart told me this package unit was not suffering from lack of mechanical cooling capacity; it was delivering everything it was designed to from the factory. It was now getting late that and I was unable to find anything wrong with the HVAC system. I told the contractor I would get back to him after I went over the numbers in my office. It was a long car ride home and I was turning the facts over again in my head, trying to find the clue I had missed. All the facts pointed to the unit delivering the correct cooling capacity, but my instincts told me he was going to have a problem the following Sunday morning.

The contractor called me up the next Monday morning telling me he solved the problem. Apparently he also believe the unit would act up the following Sunday and spent that morning on the roof of the church closely monitoring the unit. To our surprise, he found the economizer setting on this unit was set incorrectly. On Sunday mornings, the package unit’s economizer would fully open up, bringing in 100% outside air as first stage cooling. Because the economizer was at 100%, it locked out the second compressor circuit or 7.5 tons of critically needed cooling. Not only did the package unit lose half its capacity, but the air that was being pulled off the roof by the incorrectly set economizer was warm, not cold. The contractor had previously climbed up to the roof after the Sunday morning services, but by the time he made it up to inspect the unit, the economizer had determined the outside are was no longer suitable and it switched itself back over to both compressors.

In this mystery I had learned a lesson that I wanted to share. I had made a fundamental mistake by ignoring a basic rule that psychrometric charts don’t lie. The contractor and I were concentrating so hard on the supply duct distribution and refrigeration circuit that we didn’t look at the whole picture. We all learn from experience and this is one I will not forget. My advice to all the contractors out there is this – don’t look so hard for a problem that is not there that you over look the obvious, like an incorrectly set economizer.

Tony Albers is a highly successful trainer who has taught heating and air conditioning classes designed specifically to meet the needs of today’s busy technicians and engineers. For the past 33 years he has worked to advance the field of heating and air conditioning by teaching classes for IHACI, RSES, Southern California Gas Company, and San Diego Gas & Electric. In the last 23 years he has traveled extensively throughout North America for US Air Conditioning Distributors and Venstar, giving workshops and seminars for large HVAC distributors and manufacturers. Albers has been on the Continuing Education Committee for the Institute of Heating and Air Conditioning Industries and has written articles for Indoor Comfort News, HVAC Insider, and the Southern California Chapter of ASHRAE.